Tsis Siv Neeg Ntawv Cua Npuas Zaj Duab Xis Hnab Tshuab

- Yav dhau los: Automatic Air Bubble Bag Ua Tshuab

- Tom ntej: Paper Cua npuas cushion zaj duab xis lub hnab ua tshuab

Tshuab Taw Qhia

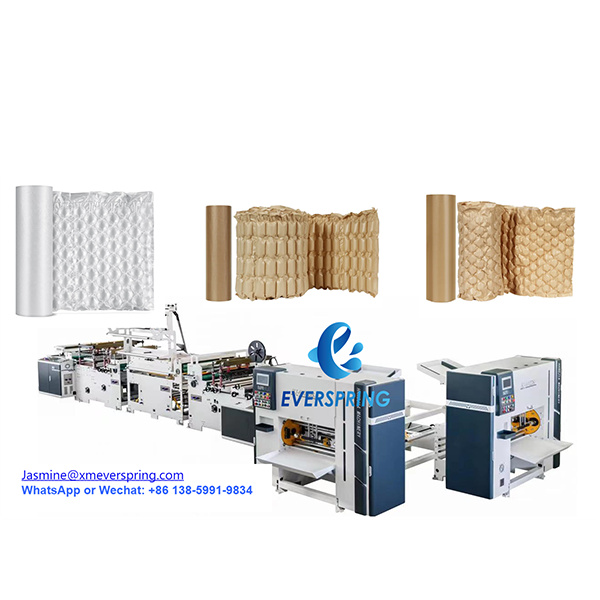

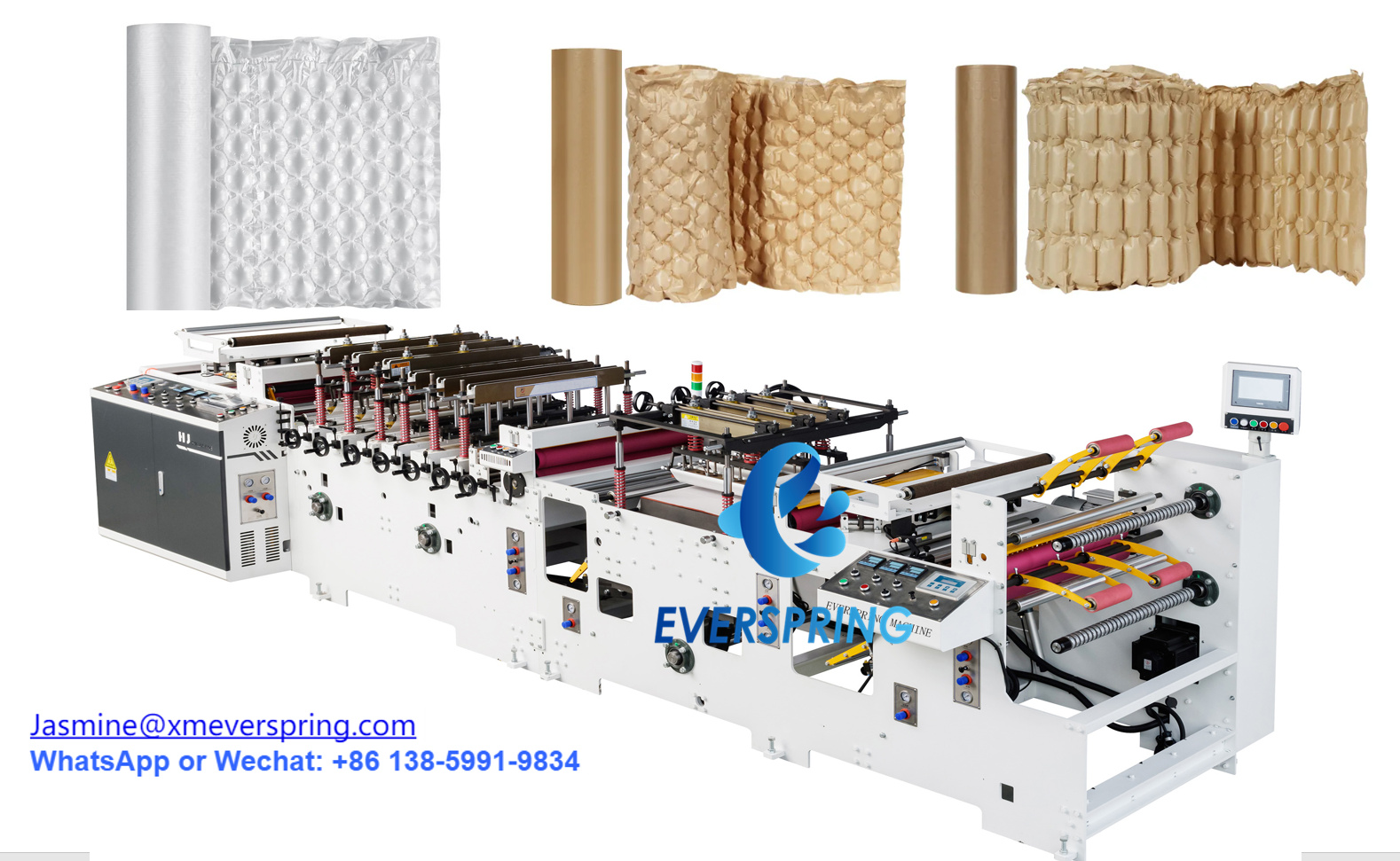

Peb tau tsim ib qho kev ua haujlwm siab tsis siv neeg daim ntawv cua cushion zaj duab xis ua tshuab, tseem hu ua tsis siv neeg daim ntawv cua cushion zaj duab xis dov tshuab, uas integrates airway sealing, film edge sealing and cross cutting.Lub tshuab no yog tsim tshwj xeeb rau PE co-extrusion ntim zaj duab xis, thiab yog siv dav hauv kev ntim cov khoom siv hluav taws xob, cov khoom seem, lub nra thiab lwm yam khoom uas yuav tsum tau ntim khoom zoo.

Peb cov ntawv tsis siv neeg tsis siv neeg lub hnab hauv ncoo ua tshuab yog tib qho ntawm nws hom hauv Suav teb.Nws muab cov kev daws teeb meem zoo rau cov lag luam kom ua tau zoo thiab sai sai ua cov huab cua zoo tshaj plaws hauv cov yeeb yaj kiab uas tsim nyog rau qhov chaw tsim khoom loj.

Qee qhov tseem ceeb ntawm peb Cov Ntawv Tsis Siv Neeg Ua npuas ncauj Cushion Film Making Machine yog:

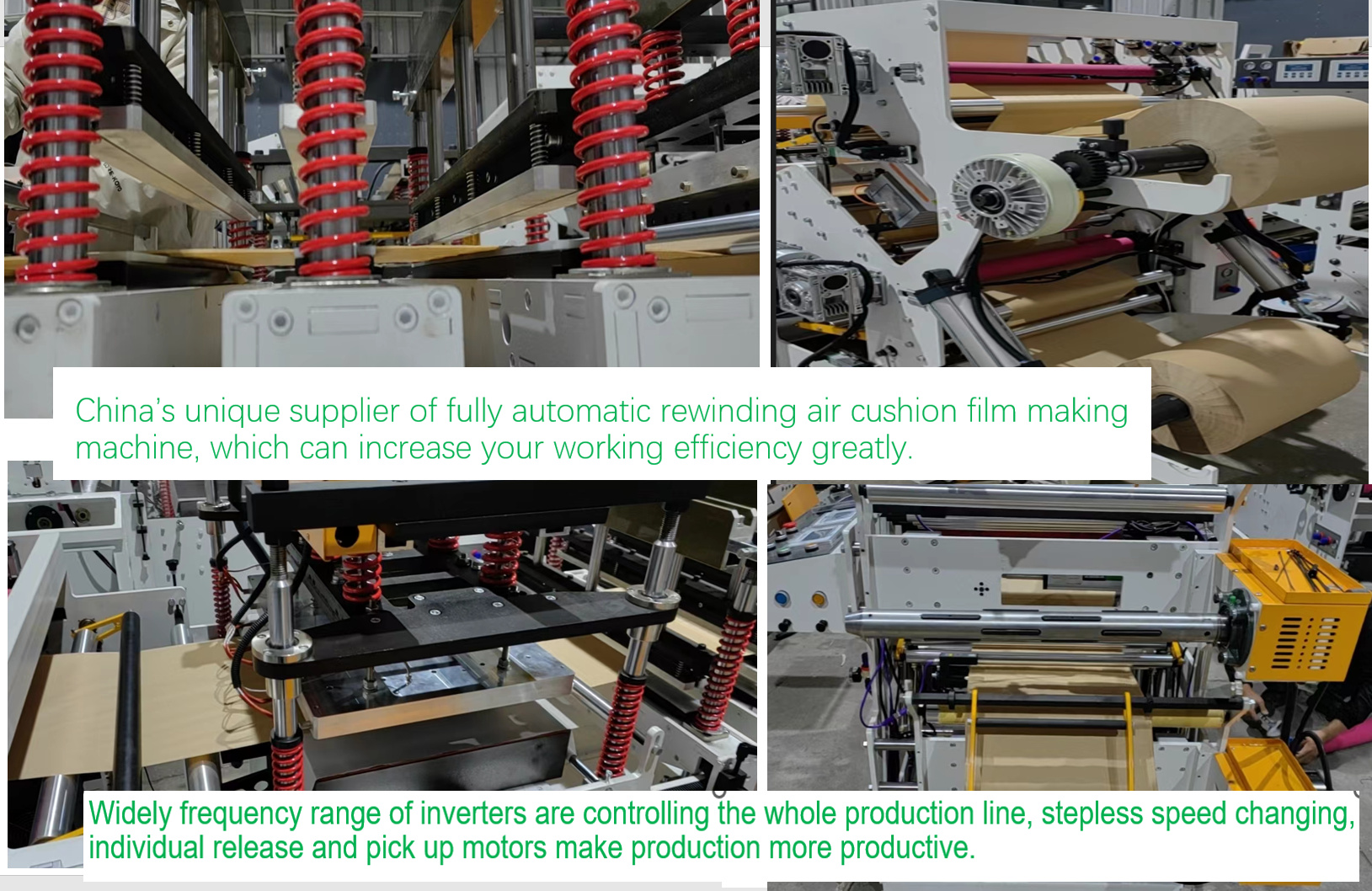

1. Cov kab ntau lawm yog tswj los ntawm ntau yam zaus converter nrog stepless hloov ceev.Independent retractable lub cev muaj zog ua rau ntau lawm ntau npaum.

2. Cov ntaub ntawv tsis siv neeg cua cushion zaj duab xis ntau lawm kab txais kev tsim cov cua tshuab hauv qhov chaw unwinding thiab unwinding, uas yooj yim rau kev thauj khoom thiab thauj khoom.

3. Lub tshuab muaj kev ua haujlwm tsis siv neeg homing, tsis siv neeg lub tswb thiab kaw ua haujlwm, uas yog tus neeg siv zoo heev thiab yooj yim.

4. Tsis siv neeg daim ntawv blister ntim tshuab yog nruab nrog tag nrho tsis siv neeg EPC ntaus ntawv nyob rau hauv lub unwinding ib feem los xyuas kom meej lub uniformity ntawm cov zaj duab xis.

5. Lub rewinding thiab unwinding ib feem ntawm lub tshuab yog txawm peem rau nrog ib tug high-kev ua tau zoo muaj peev xwm sensor, uas muaj peev xwm xyuas kom meej tsis tu ncua zaj duab xis noj thiab unwinding stability txawm nyob rau hauv kev kub ceev.

6. Yuav kom ntseeg tau tias muaj kev ruaj ntseg dua thiab raug, peb lub tshuab ua npuas cua npuas tshuab txais lub cev muaj zog reducer thiab nres kev sib xyaw ua ke, uas khiav tsis siv cov saw thiab suab nrov.

7. Lub unwinding system ntawm tsis siv neeg PE npuas zaj duab xis lub hnab ua tshuab yog nruab nrog lub qhov muag photoelectric EPC, uas ua rau cov yeeb yaj kiab smoother thiab nruj dua.

8. Peb cov tshuab yog cov qauv hloov kho dua tshiab hauv Suav teb thiab nrov heev.Lub tuam txhab ntim khoom lag luam paub zoo tau hloov kho peb cov kab cua tshuab cua cushion hnab ntau lawm.

Daim ntawv thov & cov khoom muaj feem xyuam

Peb lub Hoobkas